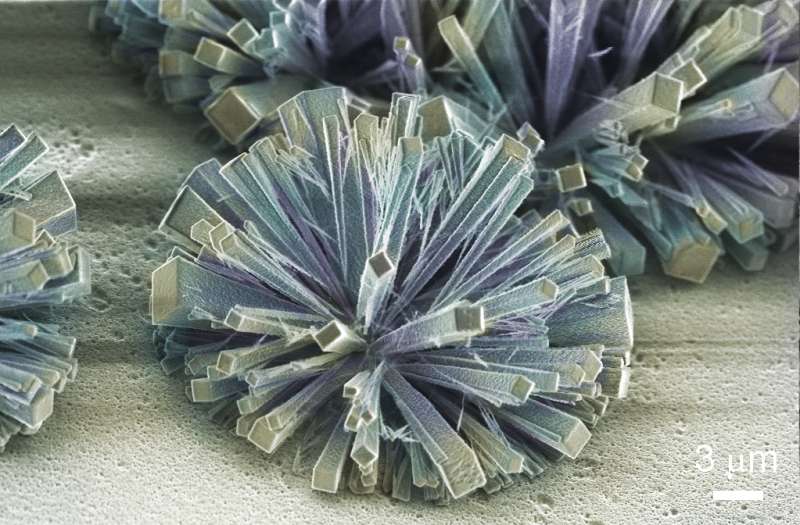

Moscow: Physicists from the Lomonosov Moscow State University have obtained micrometer-sized diamond crystals in the form of a regular pyramid. In cooperation with co-workers from other Russian and foreign research centers, they have also studied the luminescence and electron emission properties of these diamond crystals. The research results have been published in a series of articles in journals including Scientific Reports.

The researchers have described structural peculiarities of micrometer-sized diamond crystals in needle- and thread-like shapes, and their interrelation with luminescence features and field electron emission efficiency. The luminescence properties of such thread-like diamond crystals could be useful in different types of sensors, quantum optical devices, and also for quantum computing.

Technological applications of diamonds significantly outweigh their popularity as jewelry, and are increasingly widespread in industry. This is a motivation for researchers busy with elaboration of new diamond synthesis techniques. One of the problems they’ve addressed is production of needle- and thread-like diamond crystals. Such shaping of original natural and synthetic diamonds is possible due to polishing in the same way as in jewelry production. Other techniques include lithography and ion beam technologies, which help to separate fragments of desired shapes from large-sized crystals. However, such cutting techniques are quite expensive, and not always practical.

The researchers of the current study propose a technology that makes possible the mass production of small diamond crystals (or crystallites) of needle- and thread-like shapes. Their first results were published seven years ago in Diamond & Related Materials.

Alexander Obraztsov, physics professor at the Lomonosov Moscow State University, says, “The proposed technique involves determining formation of polycrystalline films from crystallites of elongate (columnar) shape. For instance, ice on a surface of a lake often consists of such crystallites, which can be observed while melting. Usually, during diamond polycrystalline films production, one strives for conditions that allow crystallites of columnar shape to tightly connect with each other, creating a dense homogeneous structure.”